The AR1 panel thermostat has been designed for the distributed process control environment with the following user-oriented characteristics:

- Simple, stand-alone, unattended operation by non-specialist personnel,

- Fully, field programmable parameters for each output,

- Complete, "seamless" integration as a slave to an external master or network, and

- Standard panel cut-out dimensions (per DIN 43700).

|

Typical applications for the AR1 are (without any other components):

- Direct control of independent cooling and heating circuits,

- Control of three-way valves,

- Control of single cooling or heating circuit selected by external command signal, and

- Thermostatic control with simultaneous driving of optical/acoustic alarms or defrosting devices.

|

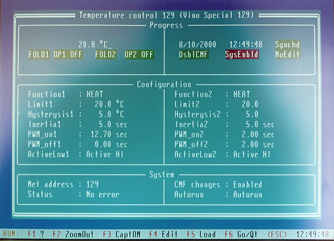

The controller features the following resources:

- Pt100 3-conductor input allowing practically unlimited cable length,

- 2 solid-state switch 230 VAC outputs,

- 12-bit A/D,

- 4 optoisolated bit inputs,

- Serial port featuring local EIA232 and Quamatic or Modbus (link in new window) network EIA485 connection,

- 4-digit-plus-sign LED display, and

- 4 front-panel membrane switches.

The front panel is protected to IP54 and is covered by a polyester membrane. The display is visible through a suitably transparent window and the switches are of the tactile type.

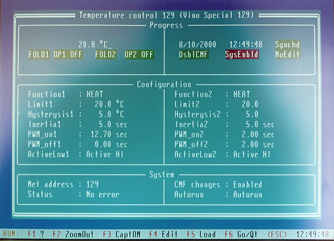

The panel thermostat is parametrically programmable for each output in the following:

- Output function. The output can be "Always ON", "Always OFF", "Heat", "Cool", "Time" and "Period",

- Reference temperature. Specifies the reference point for the heating and cooling functions,

- Reference hysteresis. Specifies the activation and de-activation points above and below the temperature reference,

- Inertia duration to maintain the output state for a minimum time following a change (typically used to limit the number of starts/stops per hour in pump applications),

- Turn On/Off times or duration. Specify the turn-on and turn-off time or duration for the "Time" and "Period" functions,

- Output PWM mark/space duration. Each output on-state can be a PWM signal of programmable mark/space duration (typically to drive alarms and visual/audible warnings),

- Logic complement of each output. Each output can be logically active-low or active-high, enabling the use of all types of actuators (e.g. normally-open and normally-closed valves),

- Autorun enable. Enables the unattended, automatic start of operation,

- Parameter change enable. Enables the alteration of programmed parameters by the operator,

- Ignore operator enable. Ignores all front panel commands, typically for remote, unattended operation,

- Serial port baud rate and net address, and

- Display index defining magnitude/state to be displayed from the panel front.

All parameters are programmable (separately or in groups) at all times (including during normal operation) via the serial port. This enables the Thermostat to be used as a slave to a master which dynamically alters set-points or performs fuzzy control.

The measured temperature value is the result of internal DSP filtering.

The four bit inputs enable control by local hardware. Each output function can be individually reversed (between heating and cooling), parameter changes can be enabled and disable the outputs.

|

The thermostat is automatically detected when in a Quamatic network.

In this case, all its data, parameters, settings etc are available on-line in hard real time.

|

Download overview, product PDF leaflets, request further information or a quote/offer

Cognito Quam Electrotechnologies Ltd

22 Pigis Ave., Melissia, Athens, 15127 Greece.

Tel/fax: +30.210.8049475

Contact us

Interested in representing, distributing and promoting Cognito Quam products? Click here.

All rights reserved. Copyright © 2000-2020 Cognito Quam Electrotechnologies Ltd.

Also see our Privacy Policy, our Guarantee and Returns Policy and About Us.

Page Keywords: Process Control, Factory Automation, Process Control Instrumentation, Panel Thermostat, Network Thermostat, Thermostat Network, Distributed Thermostatic Control.